china supply submersible slurry pump suppliers

Latest articles

Slurry Pump

china supply submersible slurry pump suppliers...

china supply submersible slurry pump suppliers 【china supply submersible slurry pump suppliers】

Read More- Reduced space requirements - Since submersible slurry pumps operate directly in the slurry, they do not require any additional support structures.

china supply submersible slurry pump suppliers...

china supply submersible slurry pump suppliers 【china supply submersible slurry pump suppliers】

Read MoreAier Machinery's team of consultants are on hand to provide you with a solution to your needs. Whether you are planning to purchase a slurry pump or need spare parts for an existing pump, we will help you determine your needs and provide advice on fine-tuning your equipment to your specific application.

china supply submersible slurry pump suppliers...

china supply submersible slurry pump suppliers 【china supply submersible slurry pump suppliers】

Read MorePositive displacement slurry pumps with limited capacity to deliver high head are used to pump slurry through pipes with very high solids concentrations.

china supply submersible slurry pump suppliers...

china supply submersible slurry pump suppliers 【china supply submersible slurry pump suppliers】

Read MoreThe size of slurry pump impeller must be considered to ensure it holds up against abrasive wear. Slurry pump impellers are generally larger in size when compared to slurry pumps for less abrasive liquids. The more “meat” the impeller has, the better it will hold up to the task of pumping harsh slurry mixtures. Just think of slurry pump impeller as a football team’s offensive line. These players are usually large and slow. Throughout the whole game they are beaten up, over and over again, but expected to withstand the abuse. You wouldn’t want small players in this position, just like you wouldn’t want a small impeller on your slurry pumps.

china supply submersible slurry pump suppliers...

china supply submersible slurry pump suppliers 【china supply submersible slurry pump suppliers】

Read MoreThe company uses advanced computer assistant engineering software to design products and technology, which makes our

china supply submersible slurry pump suppliers...

china supply submersible slurry pump suppliers 【china supply submersible slurry pump suppliers】

Read MoreIn a subsea installation, the slurry pump runs directly in the slurry and does not require a support structure, which means it is flexible and easy to install. If possible, the catch basin should be equipped with sloping walls to allow sediment to slide down into the area directly below the pump inlet. Agitators should be used when the liquid contains large amounts of solids and has a high particle density. Freestanding or side-mounted (submersible) mixers are an excellent choice for resuspended solids, especially if the catch basin is large or does not have sloping walls.

china supply submersible slurry pump suppliers...

china supply submersible slurry pump suppliers 【china supply submersible slurry pump suppliers】

Read MoreThe terms flushing and quench, often seem to be confused or misused when discussing seal support schemes for , slurry pumps, . As the concepts of a mechanical seal cartridge and a filled seal cartridge are slightly different, I will discuss them separately and in turn.

china supply submersible slurry pump suppliers...

china supply submersible slurry pump suppliers 【china supply submersible slurry pump suppliers】

Read MoreDetermine the nature of the material to be pumped

china supply submersible slurry pump suppliers...

china supply submersible slurry pump suppliers 【china supply submersible slurry pump suppliers】

Read MoreA >dredge pump is a horizontal centrifugal pump that is the heart of a dredger. It is designed to handle suspended abrasive granular materials and solids of limited size. Without a dredge pump, a stranded dredger would not be able to deliver mud.

china supply submersible slurry pump suppliers...

china supply submersible slurry pump suppliers 【china supply submersible slurry pump suppliers】

Read More

Popular articles

- Aier is pumping experts and offer some useful tips to maintain your >slurry pump.

- Auxiliary equipment

- In addition, a new level of complexity is added to an otherwise simple machine. Other parts must now be inventoried and training beyond basic spanner turning is required. When it comes to pumping rock and some of the world's most abrasive materials.

- BCT Ceramic Slurry Pumps

- Dredge Pump

- The main objective of all flush water programmes is to prevent contamination of the seals by pumped water.The flush water programme for boxes is therefore very similar to the flush water programme for mechanically sealed boxes. However there are still some obvious mechanical differences. The most notable difference is the addition of a seal (packing) between the inlet and outlet limits. This minimises the amount of flushing fluid consumed.

Latest articles

-

In this article, we will present practical guidelines and rules for slurry centrifugal pumps. We will also discuss key operating characteristics, material selection and other considerations.

-

How does a dredge pump work?

-

Capacity: 5-30000m3/h, Head: 5-120m. The company can produce different materials including High

-

sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

-

The construction aggregate industry conveys all forms of slurry, from fine sand to coarse aggregates.

-

The size of slurry pump impeller must be considered to ensure it holds up against abrasive wear. Slurry pump impellers are generally larger in size when compared to slurry pumps for less abrasive liquids. The more “meat” the impeller has, the better it will hold up to the task of pumping harsh slurry mixtures. Just think of slurry pump impeller as a football team’s offensive line. These players are usually large and slow. Throughout the whole game they are beaten up, over and over again, but expected to withstand the abuse. You wouldn’t want small players in this position, just like you wouldn’t want a small impeller on your slurry pumps.

I remembered the Stegosaurus costume my mom made for halloween one year, an impossibly complicated stretch of triangles stuffed with synthetic fluff atop a gray bodysuit (we didn’t yet know about Dinosaurs with feathers, thankfully). I remembered all of the ’70s clothing she made herself to save money and look fantastic anyway. I remembered how much she cared, and how this act of crafting was the physical manifestation of that love. What gift is more personal than a piece of clothing that won’t fit anyone else?

Enhanced Creativity and Versatility

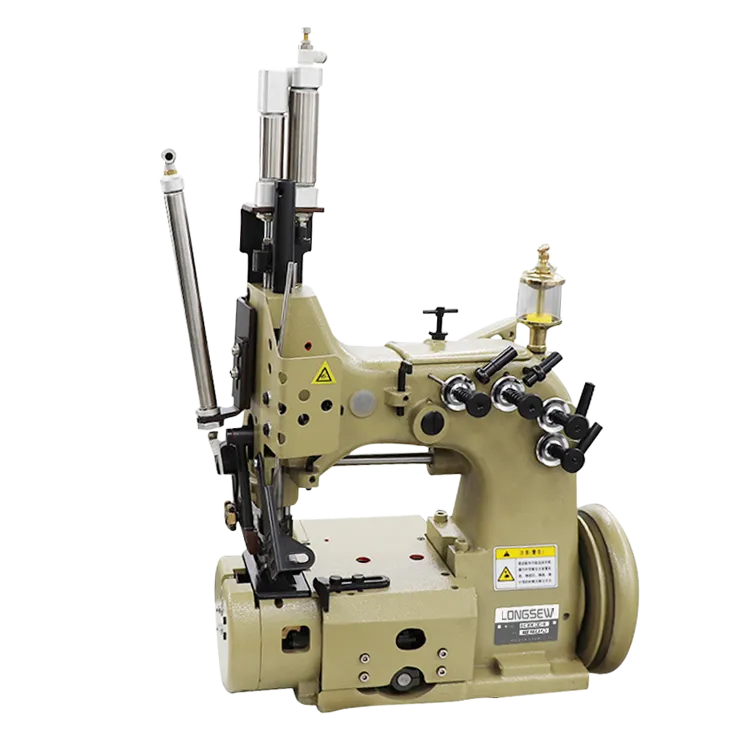

The high-speed single needle lockstitch sewing machine is a pivotal tool in the textile and garment industry, known for its efficiency and versatility. As one of the most commonly used sewing machines, it is designed to produce high-quality stitches with remarkable speed, making it an indispensable equipment for manufacturers aiming to enhance productivity.

heavy duty leather sewing machine. These machines are typically equipped with a range of stitch options, including straight stitches, zigzag stitches, and decorative stitches, allowing you to create a variety of finished looks on your leather projects. Some machines even offer programmable stitch settings, giving you even more control over the final outcome of your sewing.

Furthermore, the advent of technology has allowed for additional features such as memory functions, where users can save their favorite settings for different types of buttons or fabrics. This flexibility enhances productivity and ensures that users can switch between different sewing tasks seamlessly.

The Art of Lock Sewing A Comprehensive Guide

Moreover, specialized sewing machine retailers often have a selection of industrial machines and a knowledgeable staff that can help you select the right model to fit your specific needs. Be sure to conduct thorough research, including reading reviews and comparing different models, to ensure you make an informed decision.

2. Nylon Thread Nylon is another popular choice for heavy-duty sewing. It is known for its elasticity and resilience, making it a great option for items that may experience stretching, like bags or apparel. Nylon thread is also highly resistant to abrasion.

Benefits for Users

When selecting a single stitch leather sewing machine, it is essential to consider several factors to ensure it meets your specific needs

Sewing Machine Specials Unleashing Your Creativity

Understanding your specific requirements will lay the foundation for selecting the ideal sewing machine.

Industrial Sewing Machines: The initial investment in these machines is high. Their specialized construction, durability, and high-performance capabilities come at a premium.

4. Improved Seam Strength The two rows of stitches provide additional security to seams, which is critical in ensuring that the garment withstands wear and tear. This reliability is essential as consumers increasingly demand durable products.

use of double needle sewing machine

Conclusion

Structure and Functionality

One of the key features of the Cub sewing machine is its compact size. Despite its small footprint, this machine packs a powerful punch, with a high-speed motor that can handle even the toughest fabrics. Whether you are sewing lightweight cotton or thick denim, the Cub sewing machine can handle it all with ease. Its automatic needle threader and drop-in bobbin system make threading and bobbin winding a breeze, while its adjustable stitch length and width allow you to customize your projects to your liking.

cub sewing machine for sale